In 2024, STONELINK is proud to have contributed to the construction of the Iconic Marjorie Hotel, a landmark hospitality project in Penang, Malaysia, by supplying a curated selection of high-performance, aesthetically refined natural stones and sintered stones. As a trusted global stone supplier, we continue to partner with high-end developers and architects to deliver superior quality materials for luxury hotel environments.

This blog highlights the stone materials used, their specific applications, and how each stone enhances the design, functionality, and atmosphere of the spaces within the hotel.

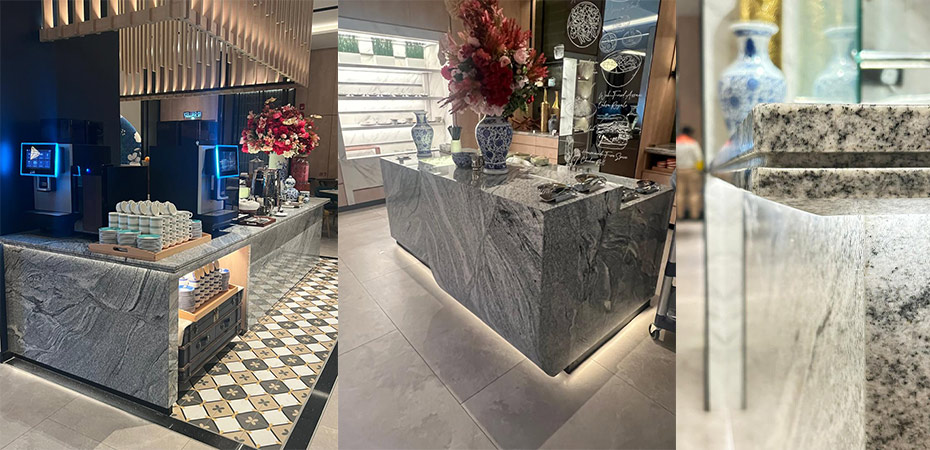

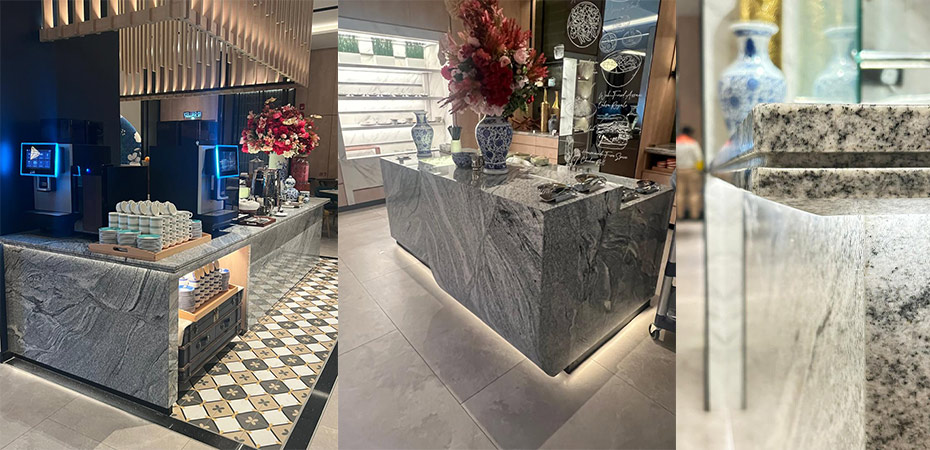

1. Viscount White Granite – Dining Area Countertops

In the hotel's dining area, Viscount White Granite was selected for the full-length countertops due to its remarkable durability, heat resistance, and timeless elegance. The flowing grey patterns on a white base deliver a clean, modern aesthetic that aligns with the venue's contemporary dining design.

Why Viscount White Granite?

(1) High resistance to staining and scratching

(2) Ideal for high-traffic hospitality spaces

(3) Harmonizes well with both wood and metallic accents

(4) Long-lasting performance in food & beverage settings

2. Indian Green Marble – Lobby Bar Counter

The Indian Green Marble adds a touch of exotic luxury to the lobby bar counter, becoming an instant focal point for arriving guests. Its deep, verdant hues and organic veining create a dramatic yet sophisticated atmosphere, reflecting the hotel's lush tropical surroundings.

Key Features of Indian Green Marble:

(1) Unique coloration inspired by nature

(2) Polished finish enhances depth and light reflection

(3) Adds contrast and richness to neutral design schemes

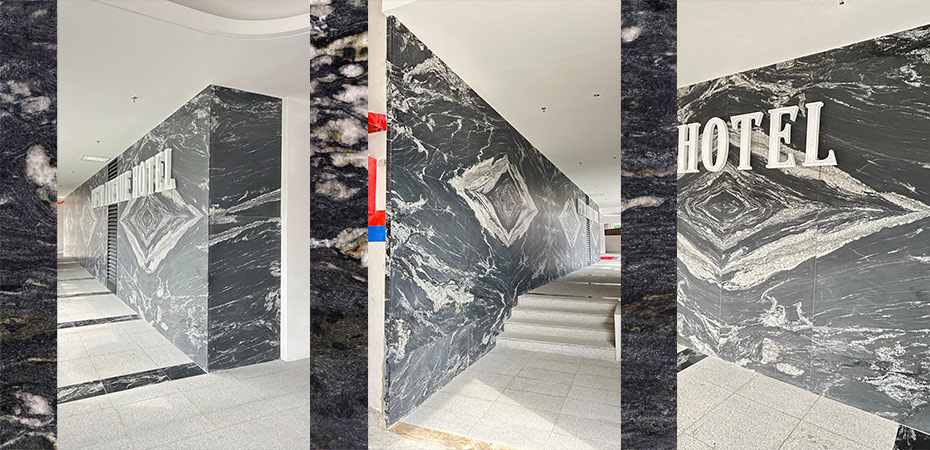

3. Romantic Grey Marble – Hotel Reception Desk

At the heart of the hotel's front-of-house is the Romantic Grey Marble reception desk. This stone combines contemporary elegance with refined texture, grounding the entrance with a commanding presence while still feeling approachable and warm.

Highlights of Romantic Grey Marble:

(1) Neutral grey tone for versatile visual integration

(2) Smooth finish suitable for sleek, modern forms

(3) Durable enough to handle high-contact zones like reception

4. Volakas Marble – Lounge Display Shelving

The Volakas Marble, sourced from Greece, is featured prominently in the lounge's display shelves and feature stands. Its soft white background and subtle grey veining convey a sense of calm sophistication, echoing the serene experience that the hotel aims to deliver.

Design Benefits of Volakas Marble:

(1) Enhances minimalist and modern interiors

(2) Soft-toned palette complements a wide range of finishes

(3) Elegant and understated luxury for communal areas

5. Grey Emperador Marble – Guest Restroom Vanities

In the guest restroom vanities, Grey Emperador Marble was chosen for its classic luxury appeal and rich veining. Its deep, earthy tones create an inviting, spa-like ambience while ensuring a durable, water-resistant surface.

Why Grey Emperador Marble Works:

(1) Dense, low-porosity surface ideal for wet areas

(2) Adds classic Mediterranean luxury

(3) Excellent visual contrast with ceramic or metal fixtures

6. Sintered Stone – Bathroom Countertops

Finally, for enhanced technical performance in the bathroom countertops, sintered stone was used. Engineered under extreme heat and pressure, this material offers a non-porous, highly resistant surface that mimics natural stone aesthetics with added resilience.

Advantages of Sintered Stone:

(1) UV, heat, and chemical resistant

(2) Low maintenance and hygienic

(3) Consistent appearance and customizable formats

STONELINK: Your Trusted Global Stone Supplier

This project is a testament to STONELINK's commitment to material excellence, client collaboration, and design integrity. Our ability to source and supply the right stone for each function and visual goal is what sets us apart in the natural stone and architectural surface industry.

Whether it's granite for performance, marble for luxury, or sintered stone for innovation, STONELINK delivers globally with consistency and care.

Explore More Projects & Contact Us

Want to learn more about how STONELINK can elevate your next hospitality or commercial project? Get in touch with our expert team today.

Email: echo@istonelink.com

Tel & WA: +86 181-5039-1891

Global Supply | Trusted Since 2012