Cambodian Four Seasons Green Marble is a wonder of the earth, a stunning manifestation of the geological forces that shaped the region over millennia. The rich mineral diversity and tectonic influences from the earth's movements have given rise to a truly exceptional stone—one that offers not just one, but a range of captivating textures and colors, all emerging from the same quarry.

Four Seasons Marble is unlike any other, as it is split into multiple distinctive varieties that showcase unique features, making it a versatile and highly sought-after material in luxury architecture and design. From vibrant jewel-like hues to delicate soft tones, the Four Seasons Green Marble series presents something for every aesthetic.

1. The Geological Wonder Behind Four Seasons Green Marble

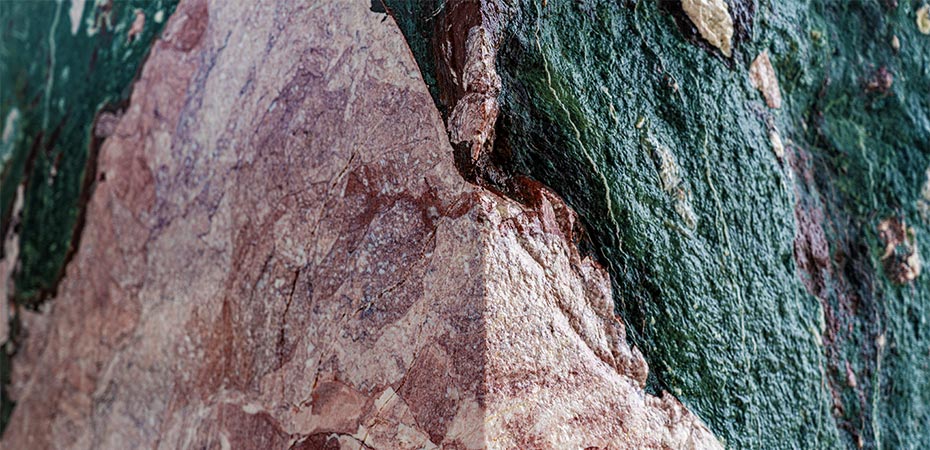

What sets Four Seasons Green Marble apart from others is the rich geological history of its origin. The dynamic earth processes that shaped this stone are visible in its varied patterns and colors, a reflection of the region’s tectonic shifts and mineral-rich composition. The continuous geological activity has allowed for the creation of not just one, but six distinct varieties of marble, each showcasing different features. The presence of high-quality mineral deposits has also enriched the stone’s unique veining and coloration, making each slab an artwork of nature.

2. The Distinct Varieties of Four Seasons Green Marble

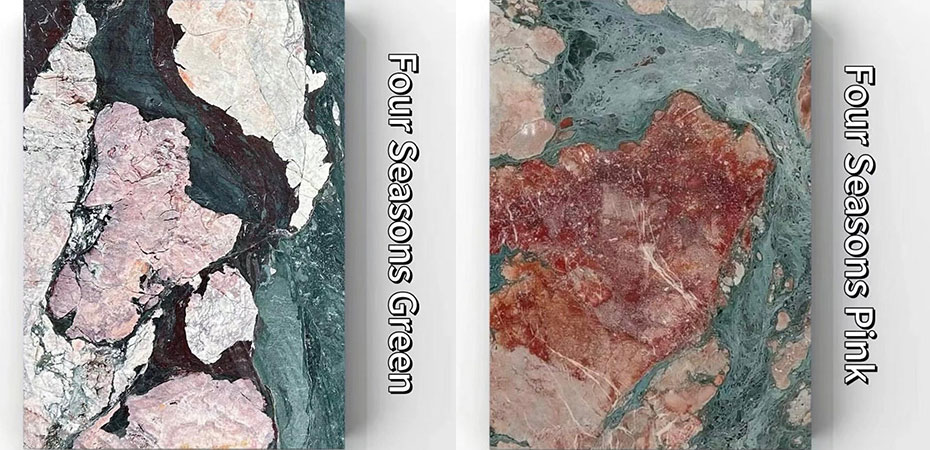

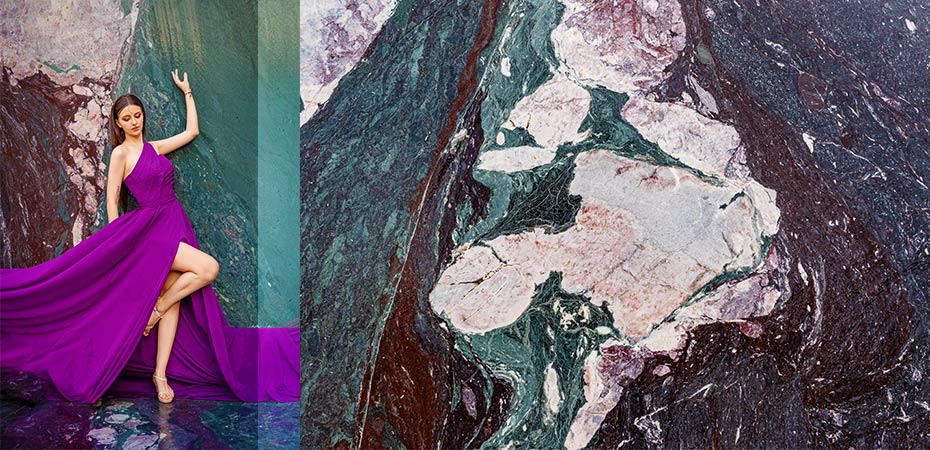

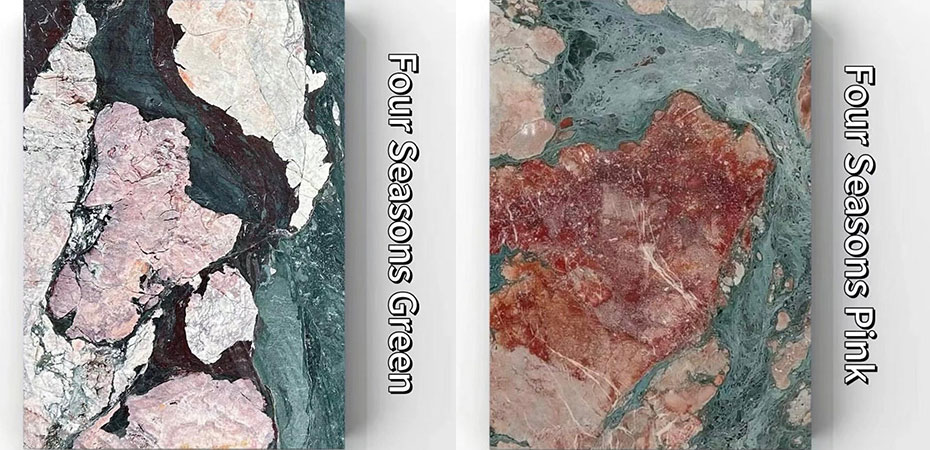

1) Four Seasons Green Marble

The epitome of the brand, the Four Seasons Green Marble variety offers a vibrant, high-saturation color with intricate veining that mirrors the gem-like, fragmented mosaic style of the original French quarries. The deep, rich green tones are adorned with bursts of gold, beige, and brown veins, creating a luxurious and vibrant aesthetic. This is the perfect choice for those looking to make a bold statement in high-end commercial or residential designs.

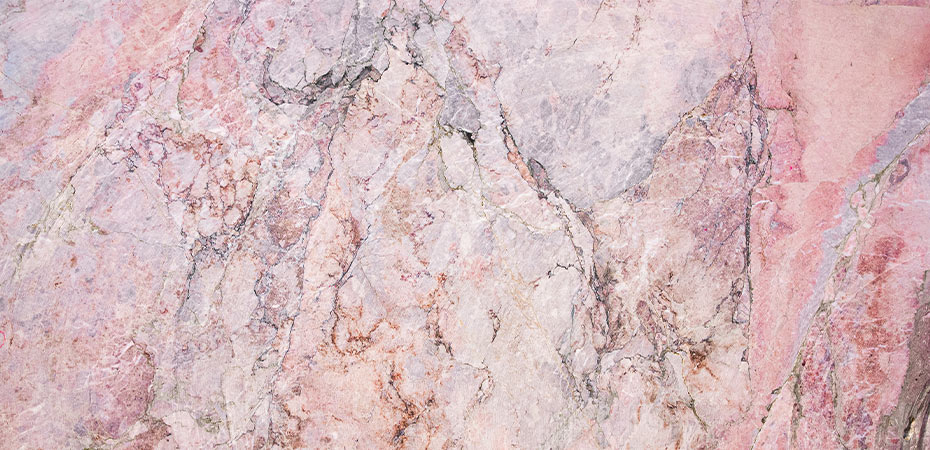

2) Four Seasons Pink Marble

A more romantic and delicate variety, Four Seasons Pink Marble blends soft greens and blush pinks. This variant offers an elegant and sophisticated hue, making it a fantastic choice for spaces that call for warmth and refinement. The combination of muted pink and green tones gives it a timeless charm that fits beautifully in both contemporary and classical settings.

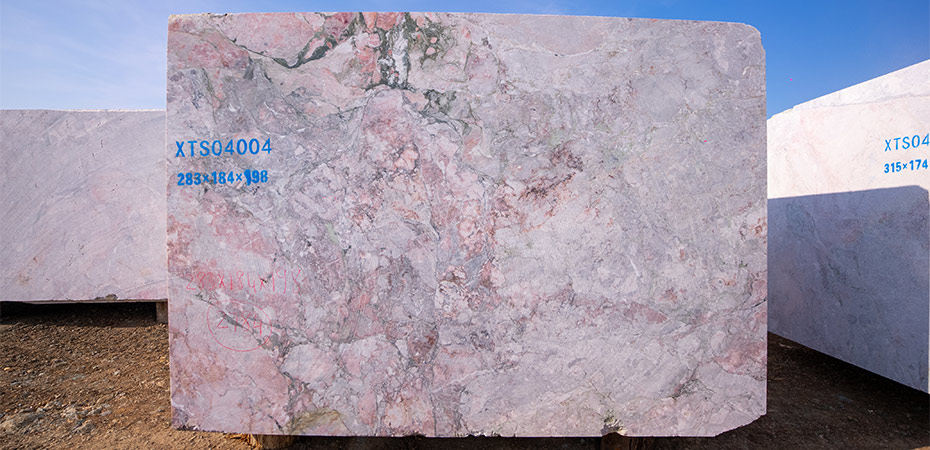

3) Four Seasons Sakura Marble

Light and airy, the Four Seasons Sakura Marble boasts pale pink hues that gently merge with light green veins. Named after the famous Japanese cherry blossoms, this variety is delicate and serene, making it perfect for creating tranquil spaces. The subtle color palette and smooth texture make it an excellent choice for residential interiors, such as bathrooms, kitchens, or decorative panels.

4) Four Seasons Panda Green Marble

With a unique blend of white and green, the Four Seasons Panda Green Marble stands out with its striking contrast and balanced elegance. The green hues are softened by the contrasting white veins, making it an ideal choice for minimalistic or modern designs. This marble’s soft sophistication works beautifully in both neutral and vibrant spaces, adding depth without overpowering the surrounding décor.

5) Four Seasons Imperial White Marble

Subtle yet majestic, Four Seasons Imperial White Marble offers a cool, gray-white base with delicate veins running through it. This variant is often chosen for its timeless elegance and clean lines, making it ideal for sleek modern spaces or luxury projects. Its neutral tone provides a perfect backdrop for vibrant accent pieces or bold architectural designs, making it incredibly versatile.

6) Four Seasons Fantastic Violet Marble

A stunning and rare variety, Four Seasons Fantastic Violet Marble features deep purple veins swirling within a mix of soft reds, pinks, greens, and golds. This enchanting marble is one of the most eye-catching in the Four Seasons collection, offering a dramatic and luxurious feel. Its captivating colors are perfect for creating statement pieces in grand lobbies, high-end interiors, or feature walls that demand attention.

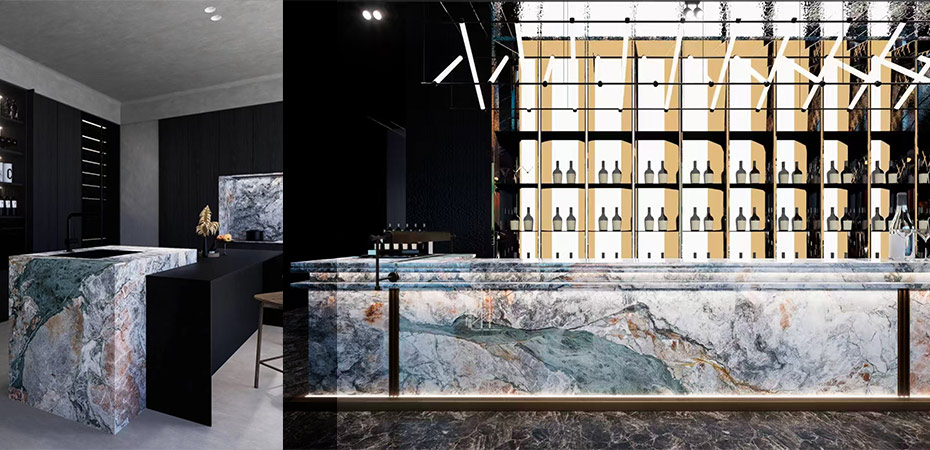

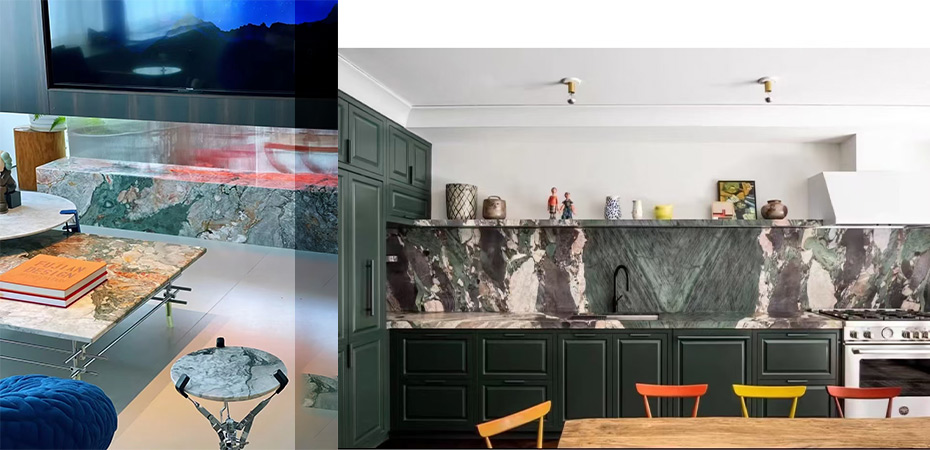

3. The Versatility of Four Seasons Green Marble in Design

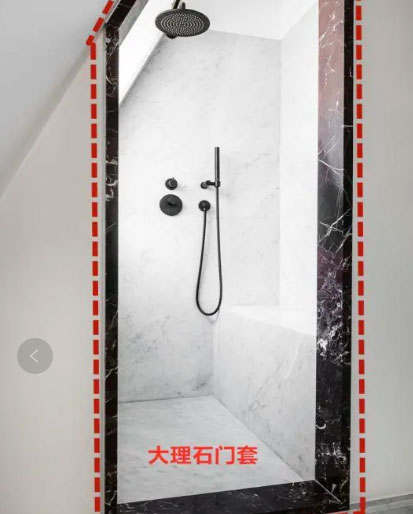

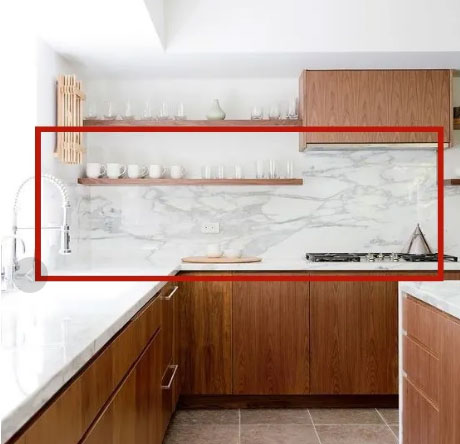

The beauty of Four Seasons Green Marble lies not just in its stunning variety of colors and patterns, but also in its versatility. Whether used as flooring, wall cladding, countertops, or decorative accents, each variety brings a distinct character to any space. The marble’s vibrant hues and luxurious textures make it the ideal choice for both modern, minimalist interiors and more traditional, opulent designs.

Its remarkable adaptability makes it suitable for a wide range of applications, including:

1) Luxury Hotels & Resorts: High-end lobbies, bathrooms, and common areas benefit from the dynamic nature of the Four Seasons Green Marble series.

2) Residential Interiors: From kitchens and bathrooms to statement feature walls, this marble’s ability to transform a space is unparalleled.

3) Retail & Commercial Spaces: Luxury retail outlets or boutique restaurants can showcase this marble’s elegance and rich textures, attracting attention and creating lasting impressions.

4) Architectural Projects: Whether used for flooring, wall cladding, or decorative features, the marble’s array of finishes brings depth and sophistication to any design.

4. The Art of Quarry Sourcing: Sustainability and Quality

One of the key factors behind the success of Four Seasons Green Marble is STONELINK’s direct sourcing from the Cambodian quarry. This method ensures that the marble’s quality is consistently maintained while reducing the environmental impact associated with other mining and shipping practices. By working directly with the quarry, STONELINK can guarantee that each block and slab of marble meets the highest standards of excellence, both in appearance and durability.

Sourcing from Cambodia also ensures that the Four Seasons Green Marble has an exclusive regional presence, making it a rare and desirable material for discerning designers and architects around the world.

The Four Seasons Green Marble offers a unique connection between earth, time, and craftsmanship. Its diverse range of styles and colors makes it an invaluable resource for anyone looking to add a touch of nature’s artistry to their project. With its origins deeply rooted in Cambodia’s rich geological landscape and a wide variety of stunning options, the Four Seasons Green Marble is set to be a timeless symbol of beauty, luxury, and versatility in the world of natural stone.